Induction tooth hardening and cut to length of coils of bowsaw blades.

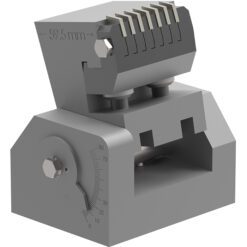

ALO 193-300 has high efficiency and low energy consumption generators with air-cooled oscillator tubes. Automatic anode current control keep the anode current constant during the whole coil. The inductors are made of copper tubing and can be custom made for different pitches and blade gauges.

The band feeder consists of two units, one acting as a feeder, the other as an adjustable brake to control the band tension. The system is designed for accurate speed and guiding and electromagnetic friction brake for optimal control of band tension.

The band is fed from the hardening unit via the loop table to the cut to length machine with magazine. Blade lengths up to 610mm are fed in one feed cycle. The punching is done with a pneumatic press. Number of blades are chosen on a keyboard and surveillance of the machine operations is done via a PLC. An air motor feeds the blades into a collect magazine, the magazine consists of a collect slot and a vertical stacking magazine.

Read more:

English

English