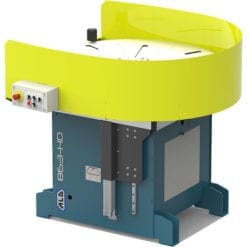

Heavy duty band saw setting machine with SGS camera system and feed roller unit

ALO 187-C together with the SGS camera system will help you to monitor and get in full control of the setting process and quality. The SGS system automatically adjust overall set and symmetry by actuators

The machine is equipped with a feed unit that is using the SGS camera system for positioning of the teeth in the setting head. A setting head, sets all teeth, both sides, simultaneously and can thereby handle both longer set groups and harder band material.

One of the advantages is the high production speed and the ability to run the bands with both tooth directions, making it unnecessary to re-coil the teeth orientation before setting.

187-C is a setting machine that can handle all segments of production (meat, fish, wood, bi-metal).

Here’s the latest features:

- Festo Servos for Precision: Powering symmetry and camera positioning along the X and Z axes. Can also be reached via ewon for remote support.

- Profinet in the coiler: This enables detailed diagnostics of all electrical devices and allows remote support.

- Siemens HMI Unified Panel: Places the highest demands on industrial control and monitoring.

- Improved Height Adjustment: A more stable height adjustment mechanism with an improved locking device, ensuring accurate and consistent performance with minimal effort.

- Sleek, Modern Design: With an updated, clean and stylish look, our machine not only performs at the highest level but also looks great. Elevate your workspace with a machine that combines functionality with modern style.

By using ALO’s cube system, or one of our single-coiler solutions together with the machine, the teeth are secured from damage and maintains the saw bands high quality. The operator is also more protected from cuts and scratches.