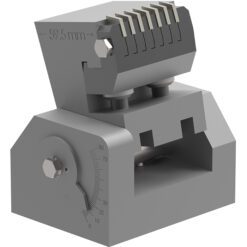

Setting and Induction Tooth Hardening of Hand Saws

ALO 486 Setting Machine and ALO 490 Induction Tooth Hardening Machine for Hand Saws are integrated in line by means of a pick and place unit that transfers the blade from the setting unit to the roller conveyor of the hardening unit.

A vision system identifies the tooth form of the first tooth such that it will be fed to the correct setting position. After this a linear feeder transports fixture and blade to a start setting position.

The feeder will feed the blade up to 150 mm per feeding as many times as required to set the complete length of the blade.

After setting is completed the linear feeder transports the blade to a transfer position where the blade is transferred to the hardening roller conveyor by the second pick and place unit.

The setting and hardening sequences are fully automatic and a PLC controls all functions.

Read more:

English

English