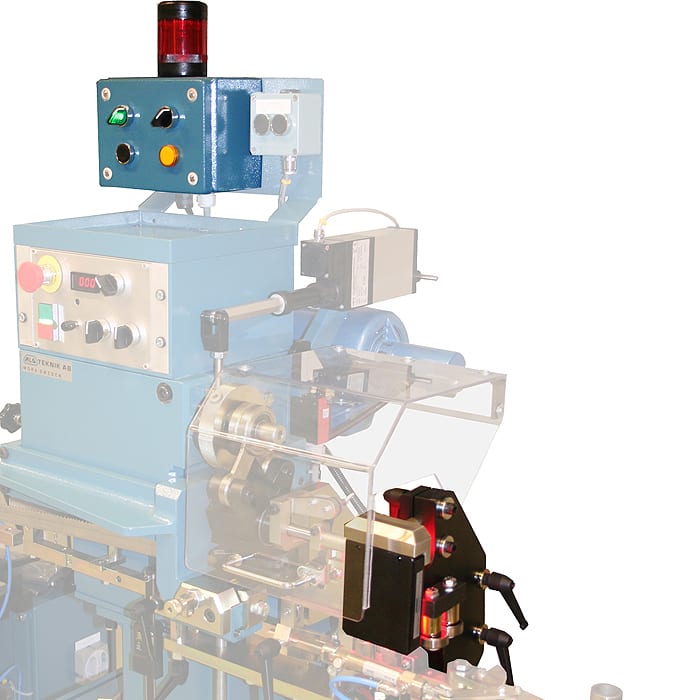

Vision system for control of index/feed in ALO setting machines

If your setting machines feed stroke is set up incorrect or if you have different faults or variations in your bands from the toothing process, there is always the risk of skipping or not feeding in the correct gullet in a VIP pattern. Your ALO setter can be equipped with a vision system to ensure that the feeding are made in the correct gullet.

This unit will stop the setting machine on the first stroke that do not correspond to your reference and will help reducing you cost for scrapping whole coils or even batches of expensive band material due to wrong set patterns. Within its view, the system can also help to inspect and detect broken or missing teeth, milling or grinding faults, blanks etc and can be set up to stop the machine if your tolerances are exceeded.

Read more:

English

English