CHRISTOFFER AND EMIL

The people behind our company are as important as the company itself.

Let´s meet Christoffer and Emil, two of our CNC-operators.

What do you do at ALO?

In our role as CNC operators, we create machining programmes for use in our various lathes and milling machines. These programmes are then used when we produce parts and components for our ALO machines.

Quality assurance is the backbone of our business, we inspect both incoming materials and end products and follow the strict quality standards of our manufacturing.

In addition, we purchase the tools needed for our operations.

We are a total of four CNC operators, Jim and Tommy are also in the team.

Which talent do you use at work?

Emil – I have a lot of computer experience, which helps me when creating programmes for the lathe/milling machine.

Christoffer – I have the ability to think three-dimensionally, this helps me to visualise the object that I am going to produce.

What is the best thing about your colleague?

Emil – Christoffer is very knowledgeable and helpful. I get very good help from him.

Christoffer – Emil is good at turning/milling parts quickly and efficiently with good results.

Which is the largest and smallest details you have milled?

We start with a piece weighing 120 kg and after 4 hours the part is ready and weighs 50 kg. The finished part has various holes and details.

The smallest detail takes 15 seconds to make.

Describe the blue ALO colour.

The blue of the sky.

Chistoffer and Emil in front of our newest milling machine Okuma M560R-V

HEIKKI AND PATRIK

The people behind our company are as important as the company itself.

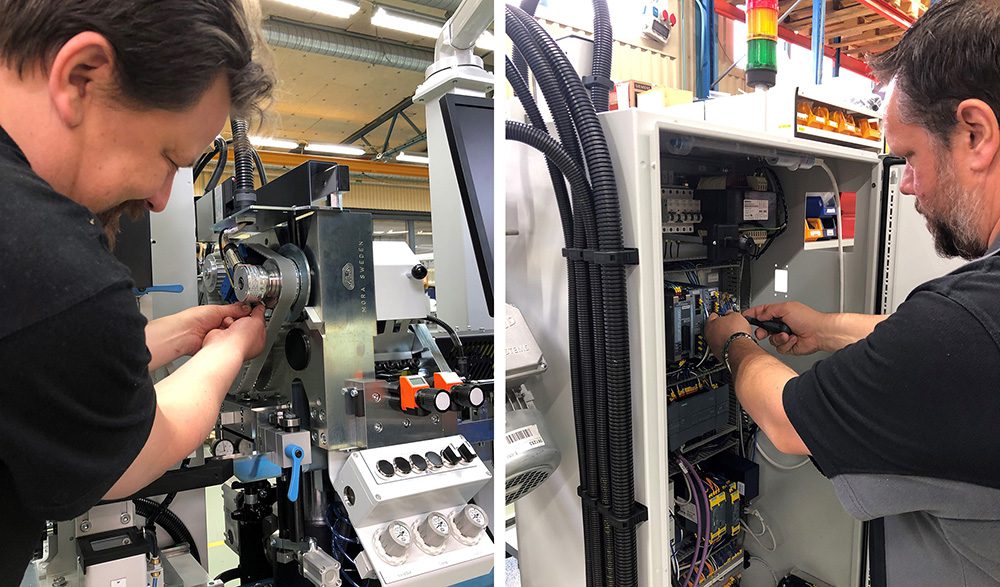

Let´s meet Heikki and Patrik, our electrical assemblers.

What do you do at ALO?

We are both responsible for all electrical installation on our ALO machines.

This includes – all electrical installation. High and low voltage and component assembly. We are also responsible for hydraulics and pneumatics. It is a varied job with many different tasks.

Which talent do you use at work?

Heikki – My eyesight is really good, which makes assembly easier. I also find it easy to read and understand electrical drawings and circuit diagrams.

Patrik – My patience is good, which helps with tricky and time-consuming assemblies.

What is the best thing about your colleague?

Heikki – Patrik is accurate, he does the right thing from the start.

He has a sense of humour, and his wiring work is well thought out, just like mine.

Patrik – Heikki is easy to work with and I learn a lot from him. He also wires just as well as I do.

Looks like you do a lot of connections and wiring?

Yes, we make about 300 electrical connections and install about 400 meters of electrical cable in a setting machine.

Describe the blue ALO colour.

Blueberry blue.

Patrik is standing up and Heikki is sitting down.

WELCOME TO ALO

We are happy to announce that six new colleagues recently have joined our company – Anders Andersson, Tommy Pettersson, Emil Eld, Magnus Matsson, Fredric Lindstrand and Elin Nelson.

- Anders is our new mechanical engineer. He graduated from technical university last year and has a practical background with experience in both machining and mechanical repairs. Anders has always been interested in mechanics, especially engines and cars. He enjoys going to the gym and biking. Recently he bought an old house which he is currently working on restoring.

- Tommy is one of our new CNC-operators and will strengthen our CNC department. He will operate our new Okuma 4-axis mill machine.

- Emil is also our new CNC-operator with 10 years of experience, most recently from Scania. He will strengthen our CNC department and will be operating ALO’s Okuma 4-axis lathe.

- Magnus has been involved in mechanical assembly, CNC-operations and trouble shooting. Magnus wealth of experience from similar jobs has helped him to adapt easily into the world of ALO.

- Fredric is our new electrical engineer. He has previously worked as a consultant in electrical design and automation.

- Elin is our new HR manager. She’s gained her previous experience from working as a recruiter at the bank Klarna, and with HR at Mora-based company Scanmast. Elin’s interests vary from spending time in nature (skiing, hiking, cycling…) to taking care of the home. She’s also recently fallen in love with knitting and will soon be finished with her first creation – a scarf!

MONIKA AND HENRIK

The people behind our company are as important as the company itself.

Let´s meet Monika and Henrik, our backbone at shipping and receiving.

What do you do at ALO?

We are both responsible for ALOs incoming and outgoing deliveries.

Incoming: Components for the machines that ALO is building and all office supplies.

Outgoing: Machines and spare parts.

Monika also keeps track of and assists the purchase orders, to give the purchasing department a helping hand.

Henrik also takes care of the machine packing before the shipping to our customers.

Which talent do you use at work?

Henrik – I like to play Tetris and that has certainly helped me when packing the machines for shipping. The goal is always to pack space-efficient to minimize the shipping environmental impact and the costs.

Monika – Baking cakes and cookies is one of my talents but at this point, I have kept that secret from my colleagues!

What is the best thing about your colleague?

Monika – Henrik is an eternal optimist and he always helps me out when I need assistance. He is also our package expert; the goods are always well and nicely packed.

Henrik – Monika is a great organizer, and she ties up any loose ends, which making my work less stressful.

We are a good team together!

Looks like you have a lot of spare parts in your warehouse!

We have 7.600 different varieties of spare parts in our warehouse, giving a total of 366,400 items.

Describe the blue ALO colour.

It is a more elegant version of the classic blue industrial colour.

Which is the widest ALO item you have sent?

A loop table to a 198-line. The package was 6,5 meters.

Thank you so much for meeting with me today.

Monika and Henrik – Thank you too Anna and now it´s time for us to take care of business!

WELCOME TO ALO

We are happy to announce that four new colleagues have recently joined our company. Kristina – CFO, Johan – Production manager, Christoffer – CNC-operator and Magnus – Mechanical assembler.

- Kristina is our new financial manager. For the past five years she has worked as an accountant at AB Kandre International in Orsa. Before that, she worked for one and a half years as a financial assistant at Grönklittsgruppen AB. Kristina studied accounting at Iterum in Stockholm between 2015-2017. Before that, she worked for fourteen years at Folksam, for seven years as an actuary and seven years as an insurance advisor. In her early years, Kristina studied for a master’s degree in mathematical statistics. In her spare time, Kristina enjoys walking and exercising.

- Johan is our new production manager. He comes from Pressmaster AB where he worked for 10 years as production leader and production technical manager.

Johan – ” I got the chance to start working at ALO which is a nice old traditional company that sees opportunities and challenges in growing to new levels in the industry.”

Johan has been involved in team sports for many years, which means he enjoys working with people and wants to build strong teams that together can help ALO to the next level. - Christoffer is our new CNC operator with 6 years of experience, most recently from Jan Uddén. He will strengthen our CNC department and will run ALO’s Okuma 5-axis milling machine. During the winter, Christoffer likes to snowboard. During the rest of the year, he likes to ride a motorbike and tinker with cars.

- Magnus will work with mechanical assembly. He comes most recently from Brandt Bil where he worked for many years as a car technician and most recently as an insurance adjuster. In his spare time, Magnus engages in various activities on the farm, tinkering with old vehicles, and spends time with his family. In winter, he fishes, snowmobiles and skis – preferably in the mountains. In the summer, he focuses on classic cars, boating, and fishing.